Exploring Innovative Mounting Hardware Solutions for Every Application

In the ever-evolving landscape of construction and technology, the importance of effective mounting hardware cannot be overstated. Whether you're working on a small DIY project or overseeing a large-scale industrial installation, the right mounting hardware can make all the difference in ensuring stability, safety, and durability. This blog delves into the innovative solutions available in the realm of mounting hardware, examining the unique benefits they offer across various applications. From enhanced load capacity to improved ease of installation, understanding the diverse types of mounting hardware allows professionals and hobbyists alike to make informed decisions that elevate their projects. Join us as we explore the latest trends and innovations, showcasing how the right choices in mounting hardware can optimize functionality and performance in any environment.

Innovative Mounting Hardware: A Comparison of Traditional vs. Modern Solutions

In the rapidly evolving landscape of mounting hardware, a clear distinction emerges between traditional and modern solutions. Traditional mounting hardware, often made from metal and requiring manual installation, typically struggles with aesthetics and flexibility. According to industry reports, over 60% of manufacturers still rely on these conventional methods, facing challenges related to weight limitations and installation time. The need for more versatile and user-friendly options has become increasingly evident.

On the other hand, modern mounting hardware solutions, such as those made from advanced composites and featuring quick-install designs, are gaining traction. Recent studies indicate that the market for innovative mounting solutions is expected to grow by 8% annually over the next five years. This shift can be attributed to the increasing demand for lightweight and aesthetically pleasing installations across various industries, from electronics to construction. For instance, companies adopting these modern solutions report a 20% reduction in installation time and a significant increase in client satisfaction due to improved design capabilities. As the industry continues to innovate, it’s clear that the future of mounting hardware lies in embracing these new technologies.

Key Features to Consider When Choosing Mounting Hardware for Different Applications

When selecting mounting hardware for various applications, understanding key features is crucial to ensure optimal performance and durability. According to a report by MarketsandMarkets, the global mounting hardware market is expected to grow significantly, bringing forward innovations that enhance versatility and reliability. The choice of material, load capacity, corrosion resistance, and ease of installation are fundamental considerations that can greatly affect the longevity and effectiveness of the mounting solutions.

Load capacity is particularly vital as it determines the weight a mounting hardware can safely support. As noted by a recent study published in the Journal of Structural Engineering, improperly rated hardware can lead to catastrophic failures, resulting in costs and safety hazards. Likewise, the right material choice—whether it's stainless steel for its corrosion resistance or aluminum for its lightweight properties—can greatly influence performance in specific environments, such as marine or industrial settings. Additionally, ease of installation shouldn’t be overlooked, as systems designed with quick-assembly features can save both time and labor costs, a factor highlighted in industry efficiency reports. Ultimately, making informed decisions based on these key features will pave the way for safer and more effective applications across various industries.

Performance Analysis: Cost-Effectiveness of Various Mounting Hardware Options

When evaluating mounting hardware solutions, one essential criterion is cost-effectiveness. A study conducted by the Research Institute for Advanced Materials Technology reveals that traditional mounting systems often incur installation and maintenance costs that can exceed 30% of the total project budget. On the other hand, innovative solutions such as modular mounting hardware have demonstrated a significant reduction in these expenses, with reports indicating savings of up to 25% on installation times alone. This efficiency is primarily attributed to their lightweight design and ease of use, which minimizes labor costs.

Moreover, a comparative analysis from the Building Hardware Council indicates that while the initial investment in advanced mounting solutions may be higher, the long-term cost benefits significantly outweigh these initial expenditures. Factors such as durability and reduced need for replacements contribute to a life-cycle cost reduction of approximately 15-20%. As industries increasingly prioritize sustainability, utilizing more efficient mounting hardware not only supports economic goals but also aligns with environmentally conscious practices, leading to an overall more viable solution across various applications.

Material Matters: Comparing Durability and Strength of Different Mounting Solutions

When it comes to mounting hardware solutions, the choice of materials significantly impacts durability and strength across various applications. In the realm of precision shooting, the latest advancements highlight that some of the top scope mounts are manufactured using high-grade aluminum and steel composites, which offer both lightweight features and exceptional rigidity. For example, innovative designs that incorporate shock-absorbing materials can enhance stability, making them more suitable for high-impact environments. This is particularly critical for professionals seeking reliable performance in challenging conditions.

Furthermore, the solar panel mounting structures industry reveals how material selection can influence longevity and efficiency. Reports indicate that the global market for solar panel mounting structures is projected to witness substantial growth from 2025 to 2035, driven by an increasing demand for robust and weather-resistant materials. PVC-coated steel and anodized aluminum are being favored for their ability to withstand harsh weather conditions while maintaining structural integrity. This shift towards durable materials not only ensures the longevity of the mounting systems but also maximizes the efficiency of solar panels, ultimately enhancing energy output.

In conclusion, whether for shooting sports or renewable energy applications, the comparison of materials in mounting solutions underscores the necessity for durability and strength in achieving optimal performance.

User Experiences: Real-World Comparisons of Mounting Hardware Effectiveness

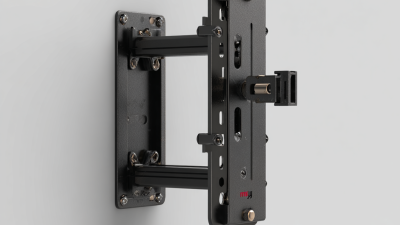

When it comes to mounting hardware, user experiences can provide invaluable insights into their effectiveness across various applications. For instance, a customer recently shared their perspective on a cloud-based TV mounting solution. They highlighted not only the ease of installation but also its versatility in accommodating different screen sizes and wall materials. This real-world experience underscores the importance of thoughtful design in mounting hardware, as it directly impacts user satisfaction and performance.

Moreover, comparative evaluations reveal stark contrasts in durability and flexibility among mounting solutions. One user noted that a standard bracket failed to support their heavy plasma screen after just a few months, while an innovative articulating mount provided both stability and the ability to adjust viewing angles seamlessly. Such firsthand accounts not only spotlight specific products but also encourage manufacturers to innovate and refine their offerings, ensuring they meet the diverse needs of customers. This emphasis on user experience ultimately drives the development of more effective, reliable mounting hardware solutions across the board.

Exploring Innovative Mounting Hardware Solutions for Every Application

| Application | Mounting Hardware Type | User Rating (Out of 5) | Ease of Installation (1-5) | Durability (1-5) | Cost Efficiency (1-5) |

|---|---|---|---|---|---|

| Home TV Mounting | Wall Bracket | 4.5 | 4 | 5 | 4 |

| Office Wall Art | Picture Hanger | 4.0 | 5 | 4 | 5 |

| Outdoor Lighting | Pole Mount | 4.8 | 4 | 5 | 3 |

| Heavy Equipment | Industrial Clamp | 4.6 | 3 | 5 | 4 |

| Shelf Display | Floating Shelf Bracket | 4.7 | 5 | 4 | 3 |

Related Posts

-

The Ultimate Guide to Choosing the Best Mounting Hooks for Your Needs

-

Top Industry Standards and Seven Key Reasons to Choose the Best Wall Bracket

-

Step-by-Step Guide to Choosing the Perfect Shelves with Drawers for Your Home

-

Reliable Quality Storage Solutions from China for Global Use in Efficient Rack Systems

-

Unlocking Space Efficiency with Racks Brackets Benefits for Every Business

-

Innovative Examples of the Best Mounting Bracket Solutions for Your Needs