Unlocking Space Efficiency with Racks Brackets Benefits for Every Business

In today's fast-paced business environment, maximizing space efficiency is crucial for operational success. The use of racks brackets has emerged as a pivotal solution for companies seeking to optimize their storage capabilities while maintaining a tidy and functional workspace. According to a 2021 Warehousing Efficiency Report, organizations that implement effective storage solutions can increase their operational efficiency by up to 30%. Racks brackets enable versatile arrangements of shelves and storage units, facilitating better organization and access to inventory. Moreover, a strategic approach to space management not only enhances productivity but also contributes to a more sustainable operation by minimizing waste and reducing the need for larger facilities. As businesses continue to grow and evolve, understanding the benefits of racks brackets becomes essential to unlocking the full potential of available space.

Understanding the Importance of Space Efficiency in Modern Business Environments

In today’s fast-paced business world, maximizing space efficiency is paramount for success. As companies continue to grow, the challenge of utilizing physical space effectively becomes increasingly important. One of the innovative solutions that businesses are adopting is the use of rack brackets, which not only enhance storage capacity but also streamline operations. By organizing tools, inventory, and equipment vertically, businesses can open up valuable floor space, creating an environment that fosters productivity and clarity.

Moreover, efficient use of space translates to cost savings and improved workflow. With the right rack systems in place, businesses can reduce clutter and minimize time spent searching for items. This organization enables employees to focus on their core responsibilities, ultimately leading to more effective teamwork and enhanced performance. In a modern business setting, where every square foot counts, investing in methods that promote space efficiency—like rack brackets—offers significant advantages that extend beyond mere aesthetics, positioning a company for long-term growth and success.

Analyzing the Impact of Rack Brackets on Inventory Management and Storage Solutions

In today's fast-paced business environment, effective inventory management and optimized storage solutions are paramount for operational efficiency. Rack brackets play a crucial role in enhancing space utilization in warehouses, allowing businesses to maximize vertical storage. Research indicates that implementing denser storage solutions can increase warehouse capacity by up to 50%, a significant boost for companies looking to leverage existing space without expanding their footprint. By integrating rack brackets into their storage systems, businesses can create flexible shelving configurations that adapt to varying inventory types and sizes.

Moreover, the rise of Automated Storage and Retrieval Systems (AS/RS) highlights the evolving landscape of warehouse management. These systems not only complement the use of rack brackets but also streamline the process of inventory retrieval and restocking, contributing to reduced labor costs and faster turnaround times. A recent report found that companies using AS/RS experienced a 20% increase in order-picking efficiency. As energy storage technologies continue to advance, businesses can also consider the environmental impact of their logistics solutions, ensuring that both storage efficiency and sustainability go hand in hand. The integration of modern storage solutions, facilitated by rack brackets, positions companies to thrive in the competitive market by enhancing both performance and sustainability in their warehouse operations.

Key Industry Statistics on Space Utilization and Cost Savings Through Rack Systems

In today's fast-paced business environment, optimizing space utilization is crucial for maintaining operational efficiency and reducing costs. The pallet racking market has experienced significant growth, with projections indicating a market size of over $9 billion by 2025. This expansion is fueled by the increasing demand for efficient storage solutions across various industries, highlighting the necessity of effective rack systems.

Statistics reveal that businesses can achieve up to 30% more space utilization by implementing advanced racking solutions such as shuttle racking and mobile racking systems. These systems not only maximize warehouse space but also enhance accessibility to goods, leading to improved productivity. For manufacturers and distributors aiming to streamline operations, investing in sophisticated racking solutions can yield substantial long-term savings.

Tips: When selecting a racking system, consider your specific storage needs and available space. Conduct a thorough analysis of your inventory turnover rates to choose the most suitable system. Additionally, regular assessments of space utilization can unveil further opportunities for optimization, ensuring that your business remains competitive in a rapidly evolving market.

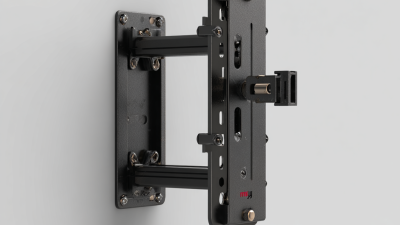

Choosing the Right Rack Brackets: Types, Applications, and Best Practices for Businesses

When it comes to enhancing space efficiency, choosing the right rack brackets is essential for businesses of all sizes. Rack brackets come in various types, including adjustable, fixed, and heavy-duty options, each designed to serve specific applications. For instance, adjustable rack brackets are ideal for environments where flexibility is crucial, allowing businesses to modify their setups as inventory levels or operational needs change. According to industry reports, organizations can save up to 30% of their storage space by utilizing correctly designed rack systems and brackets.

Moreover, best practices in selecting rack brackets include assessing the load capacity required for your specific applications. Heavy-duty brackets, which can support significant weight, are beneficial in warehouses and manufacturing settings, as they can enhance vertical storage solutions. According to recent data, more than 60% of businesses report that implementing structured storage solutions, such as rack brackets, has improved their inventory management efficiency. By understanding the types and applications of rack brackets, businesses can optimize their storage space and streamline operations, ultimately leading to cost savings and increased productivity.

Maximizing Warehouse Productivity: Real-World Examples of Rack Bracket Benefits

In today's fast-paced business environment, maximizing warehouse productivity is crucial for maintaining a competitive edge. Implementing rack brackets is one effective strategy that can transform storage efficiency. With the right rack bracket system, businesses can better utilize vertical space, allowing for more inventory to be stored without expanding the physical footprint. For example, a company that switched to adjustable rack brackets reported a 25% increase in storage capacity while streamlining their picking process, leading to faster order fulfillment.

Tip: Regularly assess your inventory to optimize the placement of items within your rack systems. By placing frequently picked items at eye level and heavier items lower down, you can improve workflow and minimize strain on employees.

Additionally, using rack brackets promotes organization, which is vital for safety and efficiency. By clearly defining storage areas and eliminating clutter, employees can navigate the warehouse more easily. Companies that adopted color-coded rack systems noted a significant reduction in time spent searching for items, which directly impacted productivity levels.

Tip: Consider implementing a barcode system alongside your rack brackets to track inventory in real time. This technology can aid in maintaining accurate stock levels and can quickly identify discrepancies, thus enhancing your overall operations.

Related Posts

-

The Ultimate Guide to Choosing the Best Adjustable Shelving: Key Insights and Industry Trends

-

The Ultimate Guide to Transforming Your Space with Adjustable Shelving Solutions

-

Ensuring Global Compliance for Best Storage Trays A Guide to Import Export Certifications

-

Exploring Innovative Industry Applications for the Best Wall Mount Hooks

-

Top Industry Standards and Seven Key Reasons to Choose the Best Wall Bracket

-

Reliable Quality Storage Solutions from China for Global Use in Efficient Rack Systems